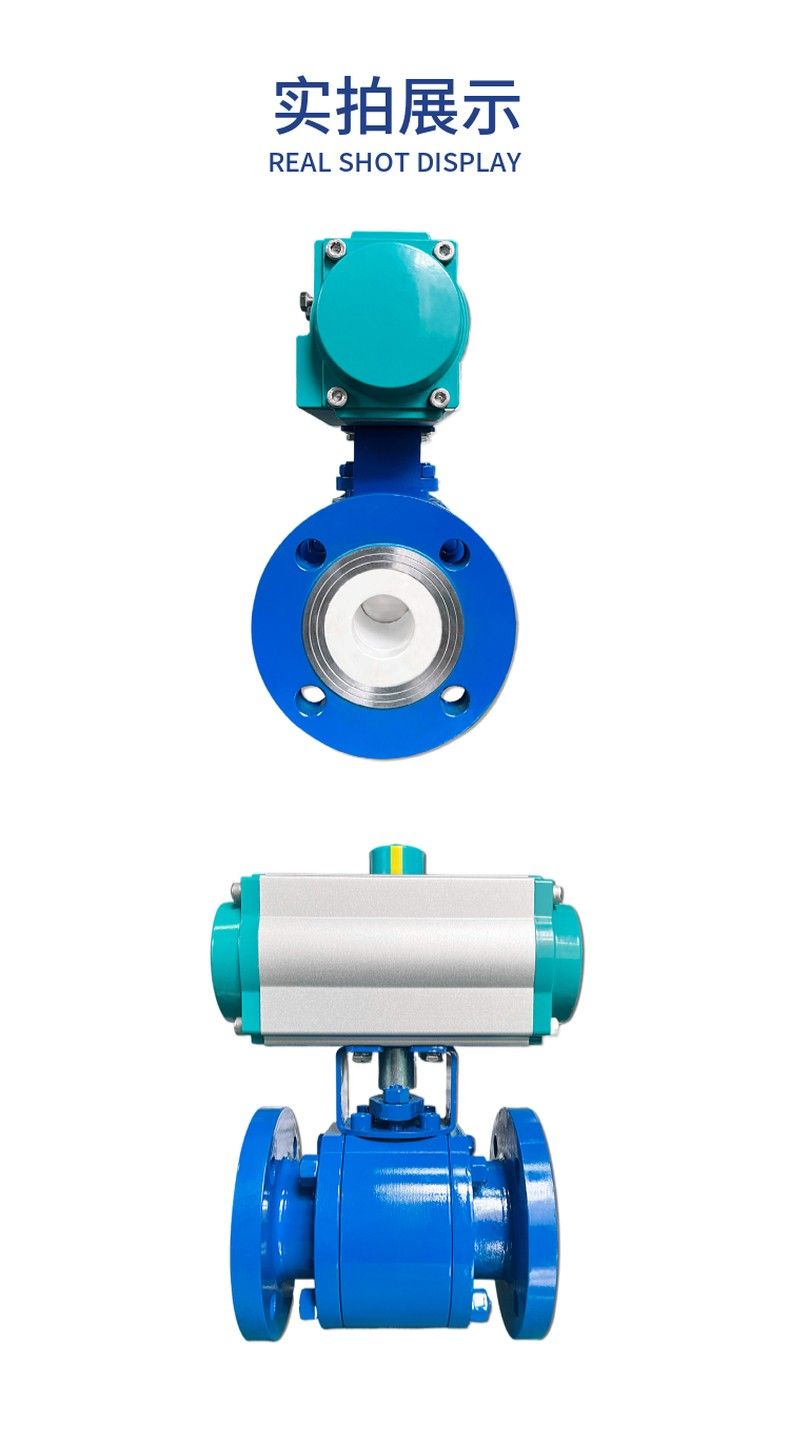

Q641TC pneumatic ceramic ball valve

Q641TC pneumatic ceramic ball valve has the characteristics of damage and erosion resistance. Used in petrochemical, metallurgy, paper making, power station, oil refining and other industries of all kinds of acid, alkali and salt gas, liquid, high temperature steam and mud conveying system. It is an ideal replacement product for titanium valve and Monel valve in strong corrosion situations. Zirconia ceramic ball valve has the advantages of low cost, high operation economy and long life (2 to 4 times that of titanium valve). Its driving methods are manual, pneumatic, pneumatic spring return, electric and so on. And can be designed according to the user's requirements of various special ceramic valves. Suitable for all kinds of acid, alkali, salt liquid, gas medium environment, hard seal valve is especially suitable for with particles, fibrous medium environment.

Features:

(1), all parts in contact with the medium are structural ceramic materials, its chemical stability and hardness is very high (Rockwell hardness HRC90), second only to diamond. Therefore, the valve has a very high loss and erosion resistance, and good heat insulation, small thermal expansion.

(2), the ball is made of grinding equipment and technology, the ball roundness accuracy is high, the surface, and the seat after lapping, the use of Zr02 ceramic self-lubricity, can achieve good sealing performance. (3), change the metal hard seal ball valve easy to leak, torque, sealing surface is not the shortcomings. (4), good ceramic, so that the valve, high reliability. Long service life, titanium alloy valve and Monel valve 2-4 times. (5), for high hardness granular medium, or soft particles but corrosive medium, this valve has the advantage, is currently the most suitable valve for such media.

The main shape and connection size:

| Q641TC-16C |

| Diameter DN | L | D | K | D1 | N - Φ d |

| f | H | W |

| mm | in |

| 15 | 1/2" | 130 | 95 | 65 | 46 | 4 - Φ 14 | 14 | 2 | 190 | 196 |

| 20 | 3/4" | 140 | 105 | 75 | 56 | 4 - Φ 14 | 16 | 2 | 195 | 196 |

| 25 | 1" | 150 | 115 | 85 | 64 | 4 - Φ 14 | 16 | 2 | 210 | 196 |

| 32 | 1 1/4" | 165 | 135 | 100 | 76 | 4 - Φ 18 | 18 | 3 | 220 | 196 |

| 40 | 1 1/2" | 180 | 145 | 110 | 84 | 4 - Φ 18 | 18 | 3 | 230 | 196 |

| 50 | 2" | 200 | 160 | 125 | 99 | 4 - Φ 18 | 20 | 3 | 265 | 196 |

| 65 | 2 1/2" | 220 | 180 | 145 | 118 | 4 - Φ 18 | 22 | 3 | 300 | 255 |

| 80 | 3" | 250 | 195 | 160 | 132 | 8 - Φ 18 | 24 | 3 | 325 | 255 |

| 100 | 4" | 280 | 235 | 190 | 156 | 8 - Φ 22 | 24 | 3 | 350 | 255 |

| 125 | 5" | 320 | 270 | 220 | 184 | 8 - Φ 26 | 26 | 3 | 375 | 255 |

| 150 | 6" | 360 | 300 | 250 | 211 | 8 - Φ 26 | 28 | 3 | 420 | 255 |

| 200 | 8" | 400 | 360 | 310 | 274 | 12 - Φ 26 | 30 | 3 | 460 | 255 |